Fundivisa

Wonderfactory is one of our most special projects. As an agency we usually work for startups, and marketing teams, but in this case Fundivisa hired us looking for a partner who could help them in digitalizing all their workflows. Fundivisa is a propeller foundry, they make propellers for clients worldwide, for big and huge ships.

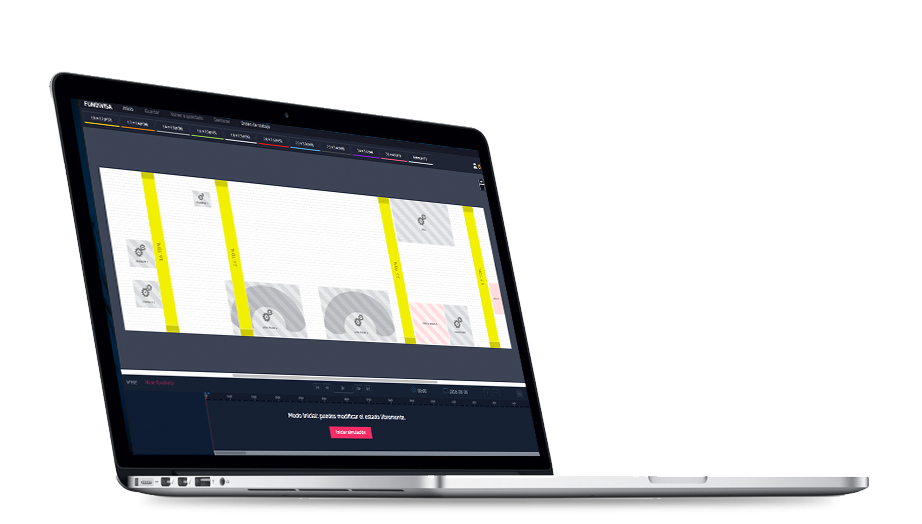

Together with the client we created a tool which allows most of the factory processes to be simulated in a geospatial frame and time frame, so that a production operator could give better work orders and plan more effectively.

Huge Interface

The interface problem was huge in this project, we had to plan it on 4D basis, taking care of actions, space and time. Making it user-friendly and simple was the biggest challenge. To achieve it we had to create a kind of music-sequencer-like interface where all the processes in the factory are displayed on a track on the timeline. To see all sequences the user just has to press the Play button.

The time axis as well as the space axis were resolved by creating a map of the factory and letting the user interact with it. This way it’s possible to place everything wherever the user wants. All the factory items can be used on the app: cranes, robots, smelting furnace…

Focus on efficiency

As most of our projects, this one was based on one premise: to create a positive economic impact. In this case we focused on efficiency, trying to boost the productivity of the workforce and to decrease power consumption, as well as optimize all the factory’s assets and spaces.

Outcomes

The app is intended to create a massive outcome on the client’s economy. If used with 100% efficiency, the electric bill can be cut off by about 60%, which is more than $200.000 annually. Also the productivity of the factory may rise about 75%, enabling the production of better pieces in a fraction of time.